The key to achieving a cost-effective and smooth supply chain is the effective management of suppliers.

A business thrives because it receives a continuous inflow of goods and services from vendors. To sustain these relationships, you’ll need to adopt solid supplier relationship management (SRM) practices.

Like CRM or customer relationship management, SRM is a discipline under supply chain management, which will help guide you in fostering healthy relationships with your business partners – in this case, your suppliers.

A business thrives because it receives a continuous inflow of goods and services from vendors. To sustain these relationships, you’ll need to adopt solid supplier relationship management (SRM) practices.

Like CRM or customer relationship management, SRM is a discipline under supply chain management, which will help guide you in fostering healthy relationships with your business partners – in this case, your suppliers.

What is SRM?

Supplier Relationship Management (SRM) is a strategic approach that organisations adopt to actively manage and nurture relationships with suppliers across their supply chain. The purpose of SRM is threefold:

By fostering a more cooperative and communicative environment, SRM builds trust and strengthens the bond between a company and its suppliers. This collaboration encourages joint problem-solving and promotes innovation, leading to the development of new and improved products or services.

- to enhance collaboration,

- to optimise supplier performance,

- to mitigate risks.

By fostering a more cooperative and communicative environment, SRM builds trust and strengthens the bond between a company and its suppliers. This collaboration encourages joint problem-solving and promotes innovation, leading to the development of new and improved products or services.

Benefits of SRM

Forging a strong relationship with your suppliers can bring a huge range of benefits to your organisation, including:

1.Higher profits

Effective SRM contributes significantly to a company's bottom line. By establishing stronger relationships with suppliers, you can negotiate more favourable terms, such as volume discounts, early payment discounts or reduced prices for bulk purchases.

Suppliers, being closer to the production processes and materials, can also offer valuable insights to improve product quality and reduce production costs if they have a good relationship with you.

Suppliers, being closer to the production processes and materials, can also offer valuable insights to improve product quality and reduce production costs if they have a good relationship with you.

2.Greater efficiency

Efficient supply chain operations are crucial for a company's success. SRM streamlines procurement processes, reduces lead times and enhances supply chain responsiveness. Improved communication with suppliers allows for better coordination and planning, ensuring timely delivery of materials and components.

A well-managed supplier base also means fewer disruptions in the supply chain, leading to smoother production processes and on-time delivery to customers.

A well-managed supplier base also means fewer disruptions in the supply chain, leading to smoother production processes and on-time delivery to customers.

3.Greater price stability

In a volatile market, price fluctuations for raw materials and components can significantly impact a company's financial performance. Effective SRM helps mitigate this risk by fostering more stable pricing agreements with suppliers.

Longer-term contracts and commitments with suppliers provide price stability and reduce exposure to sudden price hikes in the market.

Longer-term contracts and commitments with suppliers provide price stability and reduce exposure to sudden price hikes in the market.

4.Continuous improvement

Effective SRM is not a one-time process but an ongoing commitment to improvement. Regular performance evaluations and feedback mechanisms facilitate a continuous improvement cycle with suppliers.

Through open communication, both parties can address challenges, identify areas for enhancement, and jointly develop solutions. Suppliers, being key stakeholders in the supply chain, can contribute valuable insights and innovations that drive continuous improvement in product quality, processes and sustainability.

Through open communication, both parties can address challenges, identify areas for enhancement, and jointly develop solutions. Suppliers, being key stakeholders in the supply chain, can contribute valuable insights and innovations that drive continuous improvement in product quality, processes and sustainability.

Implementing SRM in your organisation

Now that you understanding the benefits of SRM, you may be wondering how to properly integrate it into your business. Below we’ve outlined what you can do in five steps.

1.Clearly outline your objectives

Before implementing SRM into your organization, it's crucial to establish clear and measurable objectives. Determine what you want to achieve through SRM, such as cost reduction, improved supplier performance, risk mitigation or fostering innovation.

Ask questions like:

Align these objectives with your company's overall business goals to ensure that SRM initiatives contribute to your success.

Ask questions like:

- What do you want out of an SRM strategy?

- What do you need from your suppliers?

- How will you measure the effectiveness of your relationship with them?

Align these objectives with your company's overall business goals to ensure that SRM initiatives contribute to your success.

2.Segment your suppliers

Not all suppliers are the same, and treating them uniformly may not yield optimal results. Segment your suppliers based on relevant criteria such as type of product, location, quantity, size and strategic importance.

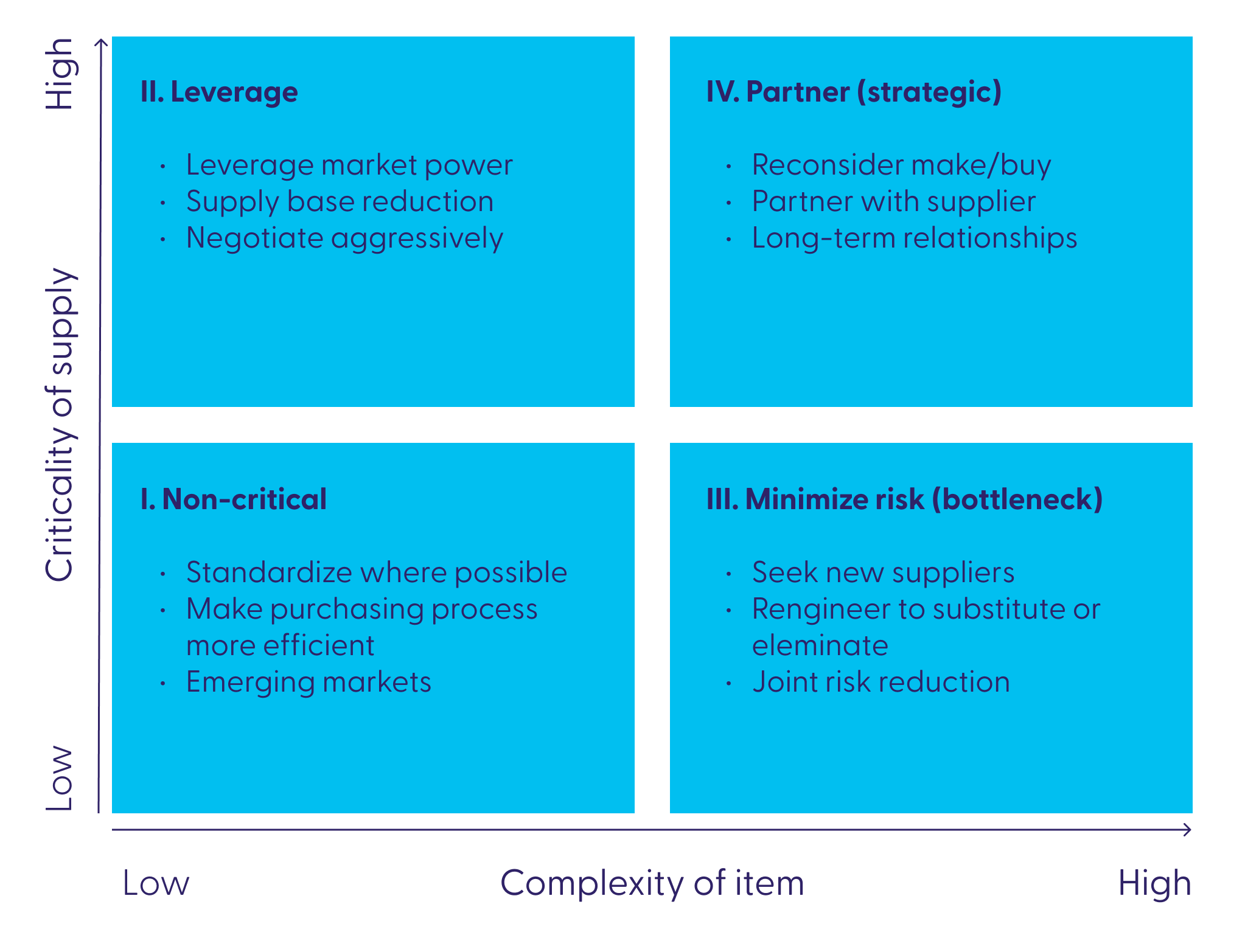

One effective segmentation approach is the Kraljic Matrix, which classifies suppliers into four categories: strategic, bottleneck, leverage, and non-critical. This segmentation allows you to prioritise resources and efforts based on the criticality and potential impact of each supplier on your business.

One effective segmentation approach is the Kraljic Matrix, which classifies suppliers into four categories: strategic, bottleneck, leverage, and non-critical. This segmentation allows you to prioritise resources and efforts based on the criticality and potential impact of each supplier on your business.

3.Create a strategy for each supplier segment

With your suppliers segmented, develop a tailored SRM strategy for each group. To refer to the Kraljic terminology:

- For strategic suppliers, for example, focus on building collaborative relationships, joint innovation and long-term partnerships.

- For bottleneck suppliers, work on risk mitigation and contingency planning to ensure supply chain stability.

- Leverage suppliers can be targeted for cost reduction initiatives and negotiation.

- Non-critical suppliers may be managed with standard procurement practices.

Source: https://procurementtactics.com/kraljic-matrix/

Each strategy should include specific goals, key performance indicators (KPIs), and action plans.

Communicate the strategy clearly with suppliers, ensuring they understand their role in achieving mutual objectives.

Each strategy should include specific goals, key performance indicators (KPIs), and action plans.

Communicate the strategy clearly with suppliers, ensuring they understand their role in achieving mutual objectives.

4.Monitor your strategy

Implementing SRM is an ongoing process that requires continuous monitoring and evaluation. Regularly track supplier performance against the established KPIs and objectives.

Use data analytics and performance dashboards to gain insights into supplier performance, delivery times, quality metrics and compliance. Engage in open communication with suppliers to address any challenges or concerns promptly.

By monitoring your SRM strategy, you can identify areas for improvement, early warning signs of potential disruptions, and opportunities to capitalise on supplier strengths.

Use data analytics and performance dashboards to gain insights into supplier performance, delivery times, quality metrics and compliance. Engage in open communication with suppliers to address any challenges or concerns promptly.

By monitoring your SRM strategy, you can identify areas for improvement, early warning signs of potential disruptions, and opportunities to capitalise on supplier strengths.

5.Continual Improvement

Continuous improvement is at the heart of effective SRM. Use the insights gained from monitoring to drive continual improvement in supplier relationships and supply chain performance.

Engage in regular feedback sessions with suppliers to discuss performance, opportunities for innovation, and areas for mutual improvement.

Encourage collaboration and knowledge sharing between your organization and suppliers. Supplier development programs can be implemented to enhance supplier capabilities and ensure they meet your evolving business requirements.

Engage in regular feedback sessions with suppliers to discuss performance, opportunities for innovation, and areas for mutual improvement.

Encourage collaboration and knowledge sharing between your organization and suppliers. Supplier development programs can be implemented to enhance supplier capabilities and ensure they meet your evolving business requirements.

Looking to develop a supplier relationship management strategy?

As an integral part of the supply chain, your responsibility is to keep the supply flow smooth and free from hindrances. That game changer is having a robust supplier relationship management in place.

If you aim for sustainable and cost-efficient business growth, you’ll have to get over the conventional means and invest in close partnerships with suppliers. Remember, your suppliers are not just companies providing you with goods and services - they are your partners.

If you’re looking for the right suppliers and partners with your business, then get in touch with our team at The Sourcing Co. We’re a sourcing company specialising in finding suppliers in the Asia-Pacific region for business across the world, helping you develop excellent relationships and achieve a cost-effective supply chain for your organisation.

You can get in touch with us right here.

If you aim for sustainable and cost-efficient business growth, you’ll have to get over the conventional means and invest in close partnerships with suppliers. Remember, your suppliers are not just companies providing you with goods and services - they are your partners.

If you’re looking for the right suppliers and partners with your business, then get in touch with our team at The Sourcing Co. We’re a sourcing company specialising in finding suppliers in the Asia-Pacific region for business across the world, helping you develop excellent relationships and achieve a cost-effective supply chain for your organisation.

You can get in touch with us right here.